If you’re hearing about re-refined engine oil and instantly picturing someone filtering old sump sludge through a sock, it’s time for an update.

Re-refined engine oil is the next big shift in lubrication tech, and Motul’s NGEN Core system is right at the sharp end. For UK enthusiasts who care about performance and the planet, understanding how re-refined engine oil works is rapidly becoming just as important as knowing your ACEA and API specs.

Motul has already rolled out NGEN products in both motorcycle (NGEN 5, NGEN 7) and automotive applications (NGEN 6, NGEN 4 and NGEN Hybrid), using regenerated base stocks rather than entirely virgin crude. Now it’s formalised that approach under the NGEN Core label, which will gradually extend across Motul’s ranges. Think of it as a new backbone technology: circular, low-carbon, but still built to cope with modern engines, turbos and long service intervals.

What is re-refined engine oil?

At its simplest, re-refined engine oil is lubricant made from used engine oil that’s been heavily processed back into high-quality base oil, then blended with fresh additives to meet the same standards as conventional premium lubricants.

Used oil from garages, dealers and waste contractors is collected and treated as a valuable raw material rather than hazardous waste to be burned or dumped. In the UK, waste oil is classified as hazardous, so it has to be dealt with under strict rules – that’s one reason re-refining is attractive; it turns a disposal headache into a circular resource.

The key difference versus the “old school” idea of recycled oil is this:

- Old stereotype: filter out the big bits, maybe de-water it, then stick it in a budget can.

- Modern reality: multiple industrial stages of distillation, hydrotreatment and fine filtration to strip out contaminants and rebuild a clean base oil that can comfortably meet modern performance standards.

Motul calls these re-refined base oils “RRBO” and uses them as the foundation of NGEN Core products.

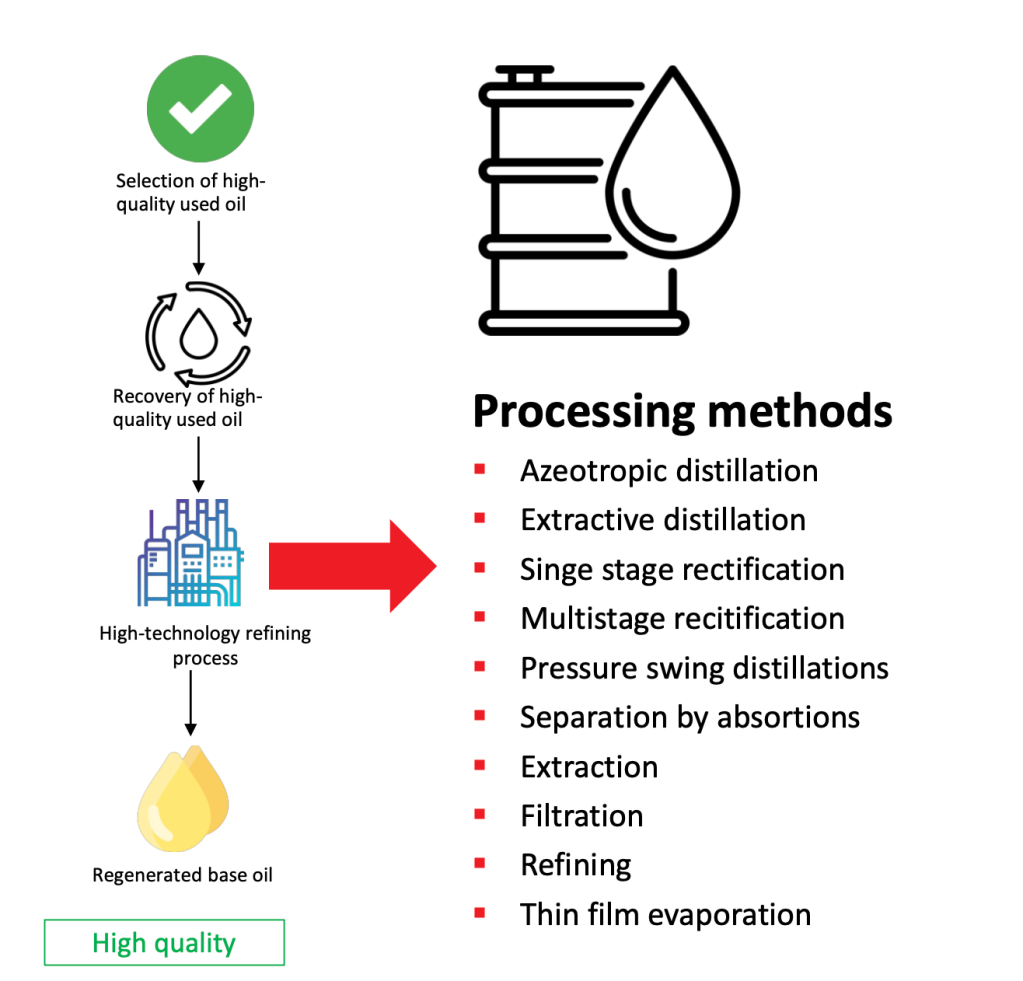

How waste oil becomes NGEN base stock

So what actually happens between the waste drum and the bottle of NGEN on the shelf? While Motul doesn’t publish the exact recipe, the process it describes looks roughly like this:

- Collection and pre-treatment

Used oil is collected, bulked and screened to remove obvious contaminants (coolant, fuel, water, loose solids). Anything completely unsuitable is rejected at this point.

- De-watering and separation

Water and light volatiles are boiled off in controlled conditions. Sludgy heavy residues—metal particles, oxidised material, degraded additives—are separated out.

- Vacuum distillation

Under vacuum, the oil is distilled into different fractions, just like base oils produced from crude. This is where old additive chemistry and much of the “used” character is stripped out. Motul explicitly references vacuum distillation as a core step in its NGEN Core process.

- Hydrotreatment / hydrofinishing

The distilled fraction is treated with hydrogen under pressure and high temperature. This saturates the hydrocarbon chains, removes remaining sulphur and nitrogen, and drastically improves colour and stability. Again, Motul highlights hydrotreatment as a key technique in its RRBO production.

- Quality control and base oil classification

The resulting base oil is tested against the same criteria as virgin stocks – viscosity index, volatility, oxidation stability and so on – and sorted into families suitable for different viscosity grades.

- Blending with fresh additives

Only at this point does it start to look like the oil you buy. Fresh additive packages are blended in to meet targeted API, ACEA and OEM performance levels.

As Motul’s UK and Ireland boss, Andy Wait, points out in the brand’s sustainability briefing, this is “a complex multi-stage process… certainly not simply ‘recycled oil’”.

Motul product packshots

Motul product packshots

Motul product packshots

Motul product packshots

Motul product packshots

Motul product packshots

Short answer: it has to – or it doesn’t get to market.

NGEN Core lubricants are formulated to meet up-to-date standards such as API SP, which is designed to tackle low-speed pre-ignition (LSPI), protect timing chains and cope with modern, highly stressed downsized petrol engines.

On the European side, passenger car lubricants must align with the ACEA Oil Sequences (e.g. ACEA C3, C5, C6) that spell out minimum performance levels for fuel economy, aftertreatment compatibility and long-drain stability.

Motul states that NGEN Core products are tested under extreme conditions and have demonstrated “uncompromising performance”, while the RRBOs themselves offer purity and performance at least equal to virgin base oils. If Motul’s technical data sheet for a specific NGEN grade confirms API/ACEA claims, those are the numbers you should rely on – and if it doesn’t, treat any unverified claims as marketing, not engineering.

Real-world example:

Take a modern turbo three-cylinder – for instance a Toyota GR Yaris – running on a low-viscosity 0W-20 or 5W-30 oil that meets the API and ILSAC specifications listed in its handbook. If a Motul NGEN passenger car oil (such as NGEN Hybrid or NGEN 6) is blended to the same API/ILSAC level and correct viscosity, and Toyota allows oils to be chosen on that basis, then from the engine’s point of view it’s seeing the same level of protection, just with a different carbon story behind it. Exact fitment still depends on the specific NGEN product data sheet and Toyota’s recommendations, so always cross-check the API/ILSAC profile and viscosity against both the handbook and Motul’s technical data before making the switch.

Why re-refined engine oil matters in the UK

From a UK perspective, there are three big reasons to care about re-refined engine oil:

- Carbon footprint

Motul reports that RRBO-based products reduce carbon emissions by around 40% versus comparable products using only virgin base oils. That’s a serious gain, especially when you multiply it across fleets and long ownership cycles.

- Waste management and circular economy

Waste oil is hazardous and must be treated accordingly, but high-quality re-refining keeps more of that carbon in useful circulation rather than burning it as low-grade fuel.

- Packaging and plastic waste

NGEN Core is supplied in bottles using 50% post-consumer recycled plastic, with a stated aim of reaching 75% PCR by 2027. That’s another chunk of environmental impact taken out of the loop without you having to change how you pour a bottle.

When you throw in UK clean-air zones and rising scrutiny around workshop waste, this shift isn’t just nice-to-have – it’s likely to become the norm.

Where Motul NGEN fits into the picture

Motul first introduced circularity into its ranges in 2023 with NGEN 5 and NGEN 7 for bikes, followed by NGEN 6, NGEN 4 and NGEN Hybrid on the automotive side. NGEN Core is the umbrella technology label that now covers all Motul products formulated with these re-refined base oils, with motorcycle MCO 4T lines (5100, 5000, 3000) due to be among the first to adopt the new branding from 2026.

Motul describes NGEN Core as “making sustainability a natural dimension of performance” – a neat way of saying that the brand expects you not to give up power, protection or drain intervals in exchange for greener credentials.

From here the plan is to extend NGEN Core across passenger car motor oils and beyond. For Fast Car followers, that’s where things get really interesting, which is exactly what we dig into in our follow-up guide on re-refined engine oil for performance cars. We also look at how fuel and oil additives can complement NGEN when we ask ‘Can additives save money?‘

Bottom line: is re-refined engine oil “safe” for enthusiasts?

Re-refined engine oil isn’t a budget compromise; in the case of Motul’s NGEN Core, it’s a fully engineered base stock that’s been through more lab work than most engines will ever see. Provided a specific NGEN product meets the API, ACEA and OEM specs listed in your handbook – and that’s always your first port of call – it should behave just like any high-quality synthetic, with the bonus of a significantly lower embedded carbon footprint.

The real test is fit-for-purpose, and that’s what we tackle next: how re-refined oils stack up when you throw boost, track days and tuning into the mix.

The post What Is Re-Refined Engine Oil? Inside Motul’s NGEN Core Tech appeared first on Fast Car.

Leia Mais.